Liquid Silicone Rubber (LSR) Injection Molding Services

Precision molding solutions for high-performance silicone components,from prototyping to mass production.

What Is Liquid Silicone Rubber (LSR) Injection Molding?

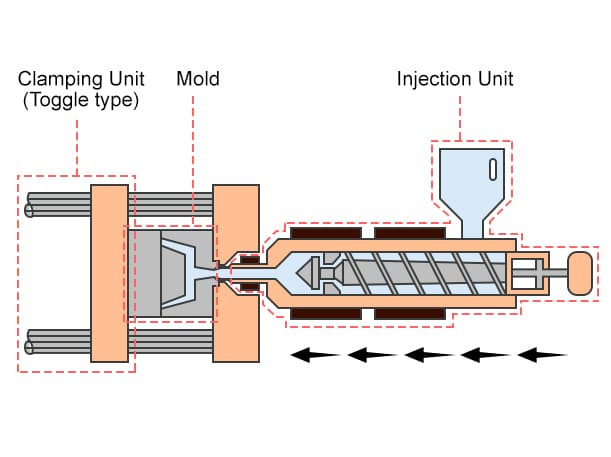

Liquid Silicone Rubber (LSR) injection molding is a manufacturing process that uses liquid, platinum-cured silicone materials to produce precision silicone parts.

In this process, two-part liquid silicone is precisely metered, mixed, and injected into a closed, heated mold. The material cures rapidly inside the mold, forming elastic and dimensionally stable components with minimal post-processing.

LSR injection molding is widely used for applications that require high consistency, complex geometries, and clean production environments, such as medical, baby care, and high-performance industrial components.

Material Composition & Molecular Structure of LSR

Liquid Silicone Rubber (LSR) is a two-part, platinum-cured silicone system designed for high-precision injection molding. As illustrated in the material structure diagram, LSR consists of a base silicone polymer combined with a crosslinking agent and reinforcing fillers. During the injection molding process, these components are mixed and cured rapidly under controlled heat, forming a stable and elastic silicone part. This molecular structure allows LSR to maintain excellent flowability before curing, while achieving outstanding dimensional stability, elasticity, and purity after molding. As a result, LSR is particularly suitable for complex, thin-wall, and high-consistency molded components used in medical, baby care, and high-performance industrial applications.

Materials & Grades We Support

We use high-purity, platinum-cured liquid silicone rubber for injection

molding applications.

• Precise metering and automated mixing for stable production

• Consistent curing with minimal material waste

• Customizable LSR grades including food-grade and medical-grade options

Our engineering team supports LSR grade selection based on part design,

application requirements, and production scale.

How LSR Injection Molding Works

LSR injection molding is a highly automated process designed for producing

precision silicone parts with consistent quality and efficiency.

• Liquid silicone components are precisely metered and mixed before injection

• The material is injected into a closed mold under controlled pressure

• Heat triggers rapid curing and crosslinking inside the mold

• Finished parts are automatically demolded with minimal post-processing

This process enables high repeatability, tight tolerances, and scalable

production for medical, consumer, and industrial silicone components.

Our LSR Injection Molding Capabilities

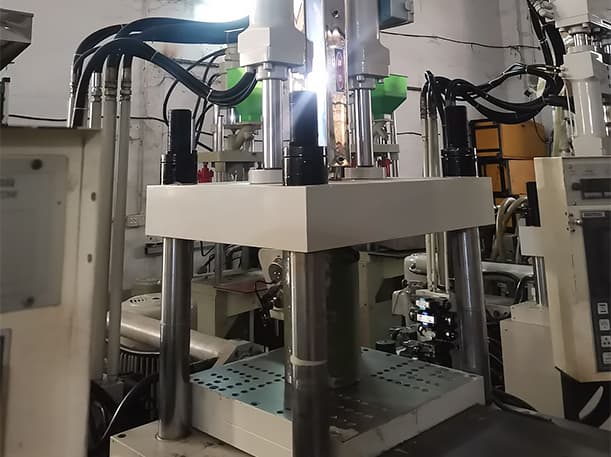

Our LSR injection molding capabilities are designed to support precision,

consistency, and scalable production.

• Dedicated LSR injection molding machines with automated control

• Precision cold runner systems for reduced material waste

• Tight tolerance control for complex and thin-wall components

• Stable mass production for medical, consumer, and industrial applications

Production parameters are optimized to ensure repeatability and long-term stability.

Why Choose Us for LSR Injection Molding

We focus on liquid silicone rubber injection molding with a strong emphasis on process stability, precision, and scalable production.

Our capabilities cover the full manufacturing cycle, from material selection and mold development to automated injection molding and quality inspection. This integrated approach enables consistent results, tight tolerances, and

reliable long-term supply.

We work closely with engineering and sourcing teams to support custom LSR projects across medical, consumer, and industrial applications.

In addition to LSR injection molding, we also provide OEM & ODM silicone manufacturing services to support custom projects from design validation to stable mass production.

Quality Control & Certifications

Quality control is integrated throughout our LSR injection molding process to ensure consistent performance and reliable production results.

From incoming material inspection to in-process monitoring and final inspection, each production stage is controlled under defined quality standards. This systematic approach helps maintain dimensional accuracy, material consistency, and stable performance across production batches.

Our production processes follow established quality control and certifications to ensure consistent performance and reliable supply for LSR injection molding applications.

Start Your LSR Injection Molding Project

Technical support from material selection to stable mass production.