Custom Silicone Logo Printing & Branding Services for OEM Mass Production

Silicone Logo Printing Methods for OEM Mass Production

At CoolniceMFG, we specialize in custom silicone printing and decoration, offering multiple techniques such as screen printing, pad printing, UV printing, and IMD. Our expert engineers ensure vivid colors, perfect adhesion, and long-lasting results for every silicone product, providing custom silicone printing solutions for your OEM projects.

Water Transfer Printing for Complex 3D Silicone Products

Ideal for silicone products with complex 3D shapes or full-wrap decorative patterns.

Commonly used for camouflage, carbon fiber, and other high-impact visual finishes where flat printing is not suitable.

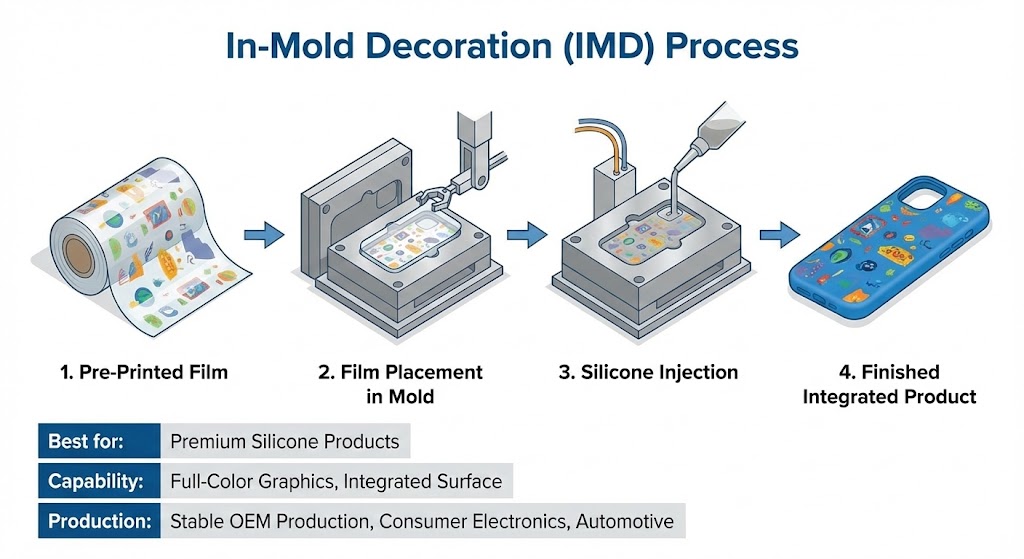

In-Mold Decoration (IMD) for Premium Silicone Products

IMD integrates pre-printed films directly into the molding process to create seamless, full-color surfaces.

Best suited for premium silicone products where visual consistency and surface quality are critical.

Pad Printing for Logos and Text on Silicone Products

Ideal for silicone products requiring clear logos or text, especially on curved or irregular surfaces.

Best suited for 1–3 solid-color designs in stable OEM production where consistency matters.

Debossed / Embossed Logos

Logos are formed directly in the silicone mold without inks or surface printing.

Offers excellent wear resistance and long-term durability for mass OEM production.

Limited to single-color logos matching the base silicone material.

Silicone Digital Printing

Silicone digital printing is suitable for OEM projects requiring flexible artwork changes, full-color logos, and fast turnaround without tooling or plates.

Heat Transfer Printing

Heat transfer printing is suitable for silicone products that require full-color graphics or detailed patterns, making it a practical choice for promotional items and short to medium OEM production.

Silicone Logo Printing Methods for OEM Mass Production

At CoolniceMFG, we specialize in custom silicone printing and decoration, offering multiple techniques such as screen printing, pad printing, UV printing, and IMD. Our expert engineers ensure vivid colors, perfect adhesion, and long-lasting results for every silicone product, providing custom silicone printing solutions for your OEM projects.

This comparison table provides an overview of common silicone logo printing methods, helping OEM buyers evaluate suitable options based on design complexity, durability requirements, and production volume.

Comparison of Silicone Logo Printing Methods for OEM Manufacturing

How We Select the Right Silicone Printing Method for Your Project

Selecting the right silicone logo printing method is not based on appearance alone.

At CoolniceMFG, our engineering team evaluates each project from a manufacturing and OEM production perspective, ensuring long-term durability, production stability, and cost efficiency — not just sample-level results.

Key factors we evaluate include:

Silicone material type and surface texture

Logo size, color count, and placement on the product

Expected usage environment and abrasion frequency

Required durability and visual performance

Production volume, tooling considerations, and cost targets

Based on these factors, we recommend a production-ready silicone printing solution that aligns with your product design, manufacturing method, and long-term OEM production goals — not a sample-only process.

For many projects, the selected printing method is closely related to the silicone molding process, such as custom silicone molding or LSR injection molding.

Water Transfer Printing for Complex Silicone Surfaces

Water transfer printing is recommended for silicone products with complex 3D shapes or full-wrap patterns that cannot be achieved using flat printing methods.

This process is commonly applied to decorative designs such as camouflage, carbon fiber, wood grain, or marble effects, ensuring consistent visual coverage across irregular surfaces.

For OEM production, water transfer printing is best suited for small to medium batch projects where visual impact is prioritized over surface wear resistance.

Our engineering team evaluates product geometry, usage environment, and order volume to determine whether this method is appropriate for stable production.

In-Mold Decoration (IMD) for Premium Silicone Products

In-Mold Decoration (IMD) is best suited for premium silicone products that require full-color graphics and a refined, integrated surface appearance.

By placing a pre-printed film directly into the mold and injecting liquid silicone over it, IMD creates a smooth and visually consistent finish without additional post-printing processes.

This method is commonly applied in stable OEM production, especially for consumer electronics accessories, automotive interior components, and selected medical or industrial silicone products where visual quality is a priority.

Compared to molded logos, IMD is less suitable for high-abrasion or heavy-wear applications. Our engineering team evaluates product usage conditions, surface contact frequency, and order volume to determine whether IMD is the optimal solution for your project.

Pad Printing for Logos and Text on Silicone Products

Pad Printing is ideal for silicone products that require clear logos, text, or simple graphics, especially on curved or irregular surfaces where flat printing methods are not suitable.

This method uses a flexible silicone pad to transfer ink accurately onto the product surface, delivering consistent results for small to medium-sized designs.

Pad printing is widely used in medium to large OEM production, offering reliable color consistency and stable adhesion across a wide range of silicone accessories and components.

Compared to full-color decoration methods, pad printing is best suited for 1–3 solid-color designs rather than complex gradients or full-wrap patterns.

Debossed / Embossed Logos for Long-Term Silicone Branding

Debossed and embossed logos are ideal for silicone products that require long-term branding durability without relying on inks or surface printing.

By forming the logo directly into the mold, this method creates a raised or recessed design that becomes an integral part of the silicone product itself.

Molded logos are widely used in mass OEM production, particularly for silicone accessories, industrial components, and promotional items that are frequently handled or exposed to wear.

Compared to printed decoration methods, debossed and embossed logos are limited to a single color (the same as the base material) but offer exceptional wear resistance and zero risk of ink fading or peeling.

Silicone Digital Printing for Full-Color Silicone Graphics

Silicone digital printing applies ink directly onto the silicone surface using digital printing technology. This method is suitable for projects that require full-color logos, variable designs, or short-run customization without the need for printing plates or films.

Digital printing enables high-resolution graphics and precise color reproduction, making it ideal for promotional silicone products, branded accessories, and designs with frequent artwork changes.

Compared to traditional printing methods, silicone digital printing is best suited for small to medium production volumes. While it offers excellent visual flexibility, it is less wear-resistant than molded or IMD logos, and is therefore recommended for applications where visual impact is prioritized over long-term abrasion resistance.

Silk Screen Printing for Logos and Graphics on Silicone Products

Silk Screen Printing is ideal for silicone products that require clear logos, text, or simple graphics, especially on flat or slightly curved surfaces where consistent ink coverage is required.

This method transfers ink onto the silicone surface through a mesh screen, allowing for stable color density and strong ink adhesion, making it suitable for designs with solid colors and defined edges.

Silk screen printing is widely used in medium to large OEM production, offering reliable repeatability and cost efficiency across a wide range of silicone accessories, mats, covers, and industrial components.

Compared to full-color decoration methods, silk screen printing is best suited for 1–3 solid-color designs and is not recommended for complex gradients, photographic images, or full-wrap patterns.

Production Control & Quality Assurance for Silicone Printing

In-house printing lines

Color consistency control

Adhesion and abrasion testing

Pre-production sampling approval

Batch consistency inspection

All silicone printing processes are managed under controlled production conditions to ensure color consistency, adhesion stability, and repeatable quality across mass production batches.

Not Sure Which Printing Method Fits Your Product?

We provide a full range of eight professional printing and surface decoration techniques for silicone and plastic products:

Debossed / Embossed Logos, Silicone Screen Printing, Pad Printing, Heat Transfer Printing, Water Transfer Printing, Digital UV Printing, In-Mold Decoration (IMD), and Co-Injection Molding (Two-Shot Molding).

Each process has unique advantages in appearance, durability, and cost — ensuring the best fit for your product design and branding needs.

Your choice depends on surface shape, color detail, and production volume.

-

Screen Printing suits flat silicone surfaces requiring bold, vibrant colors.

-

Pad Printing works best for curved or irregular parts.

-

Digital UV Printing is ideal for short runs or gradient effects.

-

IMD and Co-Injection Molding integrate graphics during molding for maximum durability.

Our engineers will assess your design and recommend the most efficient and cost-effective solution.

Yes. CoolniceMFG uses special silicone-based and UV-curable inks that bond strongly to flexible or rigid substrates. With proper surface treatment, we can achieve excellent adhesion on soft-touch silicone, TPE, ABS, and PC materials.

All our prints are heat-cured or UV-cured to ensure excellent color fastness, abrasion resistance, and UV stability.

Techniques like IMD and Co-Injection Molding embed the design within the product layer itself, providing long-term wear and chemical resistance even in demanding environments such as automotive interiors or outdoor gear.

Absolutely.

-

Digital UV Printing supports full-color CMYK and gradient effects.

-

Heat Transfer and Water Transfer deliver detailed, seamless multi-color graphics.

-

Pad Printing allows precise color registration for small logos.

We can also match Pantone colors upon request to maintain brand consistency.

Yes. We only use FDA, LFGB, and REACH-certified inks and raw materials. These are non-toxic, odorless, and suitable for food-grade, skin-contact, or baby-care silicone products. Safety and compliance are verified for every production batch.

We offer flexible options — from small prototype runs (500 pcs) to mass production (100,000+ pcs).

Lead time:

-

Samples: 5–7 days

-

Bulk production: 10–20 days depending on printing method and quantity.

Express production is also available for urgent promotional projects.