Custom Silicone Products: OEM & ODM Manufacturing Process

OEM & ODM Silicone Manufacturing Services

Coolnicemfg OEM & ODM services help brands and distributors turn silicone product ideas into reality.

From product design, mold development, and prototyping to mass production and packaging, our factory supports full-cycle manufacturing for custom silicone products.

With 20+ years of silicone manufacturing experience, we work with global private-label brands, Amazon sellers, retailers, and trading companies to deliver stable quality and reliable production.

Whether you already have drawings or just an idea, our engineering team will support you through the entire development process — ensuring functionality, safety compliance, and cost-effective manufacturing.

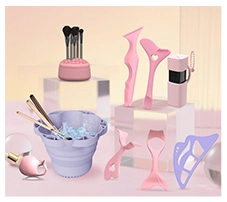

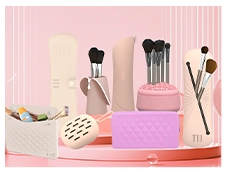

Customized Silicone Products for Bulk & Wholesale Orders

OEM & Wholesale Silicone Product Series

We offer a wide range of silicone product series designed for OEM, ODM, and wholesale buyers.

All categories below support bulk production, custom molds, logo branding, and packaging customization.

Factory-direct supply for brands, distributors, and large-volume projects.

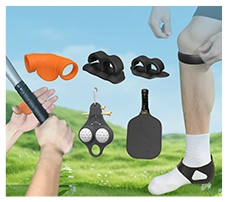

Silicone Outdoor Sports Products

Silicone Baby Teething Products

Silicone Educational Baby Toys

Full Customization for Silicone Products Options

Coolnice offers full OEM & ODM customization services for silicone products, backed by 23+ years of manufacturing experience. From custom mold development to Pantone-matched colors and packaging, we help you build competitive, market-ready silicone solutions tailored to your brand.

Surface

Size

Exterior

Material

Packing

Colors

Mold

Branded Logo Customization for All Silicone Products

Coolnice supports OEM & ODM branding services. From logo printing to full-package customization, we’ve collaborated with dozens of brands to bring their ideas to life.

Custom Silicone Colors & Shape Design Services

Coolnice provides full customization for your silicone products, from shape to color.

Our design team supports:

Custom 3D modeling based on your ideas

Flexible color matching with Pantone reference

Color sample confirmation before production

We turn your creative concepts into high-quality, market-ready silicone products.

Custom Accessories to Match Your Brand

Customize hanging straps, tags, and clips to match your brand. Our optional accessories enhance both function and style, perfect for promotions or retail packaging.

Custom Packaging

Create custom packaging that reflects your brand style. From simple boxes to full-color retail packaging, we help you stand out on shelves and strengthen brand identity.

Why Brands Choose Coolnice Sillicone Manufacturing

High-Precision CNC Machining forSilicone Molds

At Coolnice, we use high-precision CNC machining with a ±0.01 mm tolerance to produce molds for custom silicone products.

Our real-time monitoring and Coordinate Measuring Machines (CMM) ensure zero-defect results, helping you achieve consistent quality in mass production.

Production Machinery

30 injection machines & 10 auto lines, Producing 5M+ silicone parts/month with <0.5% defect rate.

Factory Overview

3000 m² factory with integrated testing. Lean setup for fast, reliable, high-volume output.

Raw Materials

100% non-toxic silicone, globally certified: FDA, RoHS, ISO 9001, zero emissions.

OEM & ODM Services

OEM & ODM Services

PATENT CERTIFICATE

Our Exhibition

FAQ

Yes. We specialize in OEM and ODM silicone manufacturing, including custom mold development, product design, material selection, and mass production. All projects are handled directly by our factory for bulk and wholesale orders only.

OEM services are based on your existing designs or specifications, while ODM services include product design and development from concept to production. We support both models depending on your project requirements and order volume.

MOQ depends on the product type, customization level, and tooling requirements. In most cases, OEM and ODM projects start from bulk quantities, and we do not support retail or single-piece orders. Please contact us with your project details for confirmation.

Yes. We offer full customization options, including logo branding, color matching, material formulation, surface finish, and packaging design. All customization services are available for OEM and wholesale manufacturing projects.

Yes. We provide in-house silicone mold development, including structural design, tooling, and mold testing. Custom molds are developed exclusively for OEM and ODM bulk production projects.

Our OEM and ODM silicone products are widely used in beauty, kitchenware, baby products, household, outdoor, and medical-related applications, serving brands, distributors, and project-based buyers worldwide.

Yes. We support silicone products that meet international standards and compliance requirements such as FDA, LFGB, and other market-specific regulations, depending on your target market and application.

Didn't find what you want?

If you do not find what you are looking for in the above, you can contact us.