Silicone Rubber Compression Molding Technology

Precision compression molding for solid silicone components with stable quality and scalable production

What is Silicone Compression Molding?

Silicone compression molding is a manufacturing process used to form solid silicone rubber parts by placing pre-measured silicone material into a heated mold cavity.

Under controlled heat and pressure, the silicone flows to fill the mold shape and cures into a finished component with consistent density, strength, and surface quality.

This process is especially suitable for solid silicone products that require high durability, precise geometry, and stable material performance, making it widely used in industrial, consumer, medical, and food-grade silicone applications.

Compared with injection molding or liquid silicone rubber (LSR) molding, compression molding offers advantages in tooling cost control, material efficiency, and structural strength, particularly for medium-to-large solid silicone parts or products with thicker cross-sections.

Large-Scale Mold Workshop with Extensive Tooling Capacity

Our in-house mold workshop is designed to support large-scale silicone compression molding projects with high stability and efficiency.

We maintain a dedicated mold storage and management area, allowing us to handle a wide range of mold sizes, structures, and cavity configurations for different solid silicone products.

With a well-organized tooling system and experienced mold technicians, we are able to ensure fast mold changeovers, consistent production quality, and long-term mold durability throughout repeated manufacturing cycles.

This level of tooling capacity enables us to support OEM and ODM projects at different production stages, from pilot runs to continuous mass production.

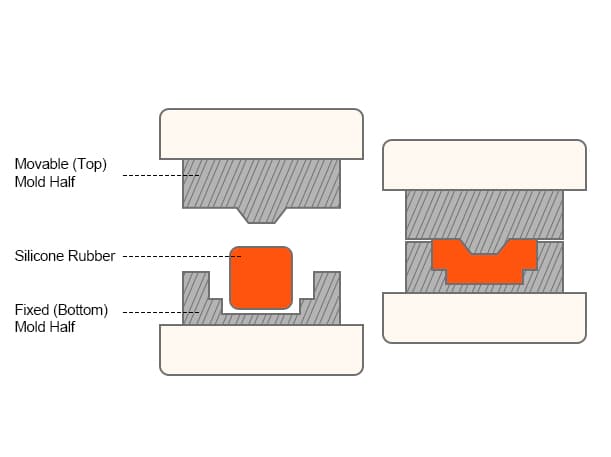

How Silicone Compression Molding Works?

Silicone compression molding is a forming process that uses heat and pressure to shape solid silicone material inside a metal mold.

In this process, the silicone is first placed into the mold cavity, then compressed and heated until it cures. Once the curing cycle is complete, the mold is opened and the molded silicone part is removed.

This method is commonly used when stable material structure, high durability, and consistent part quality are required.

Metal molds are manufactured and refined using CNC machining to achieve precise cavity dimensions and stable performance during compression molding.

Solid silicone material is prepared in controlled quantities, offering non-toxic, heat-resistant, and stable performance for compression molding.

Pigments are blended into the silicone compound to achieve uniform color distribution and stable material properties before compression molding.

The prepared silicone compound is cut into specific portions and accurately weighed to ensure consistent material volume for compression molding.

Pre-measured silicone material is placed into the heated mold and compressed under controlled temperature and pressure to form the final shape.

After curing, the mold is allowed to cool, and the molded silicone part is carefully removed to maintain shape stability and surface quality.

Excess silicone material is removed from molded parts to improve appearance, fit, and functional consistency.

Molded silicone parts are inspected for appearance and consistency, then packaged to protect product condition before shipment.

Applications of Silicone Compression Molding

Silicone compression molding is widely applied across industries that require material stability, durability, and consistent performance.

Kitchen & Food-Contact Products

Beauty & Personal Care

Home & Household Products

Consumer Electronics & Devices

Medical & Healthcare

Automotive & Industrial Components

Why Choose Our Silicone Compression Molding Capabilities

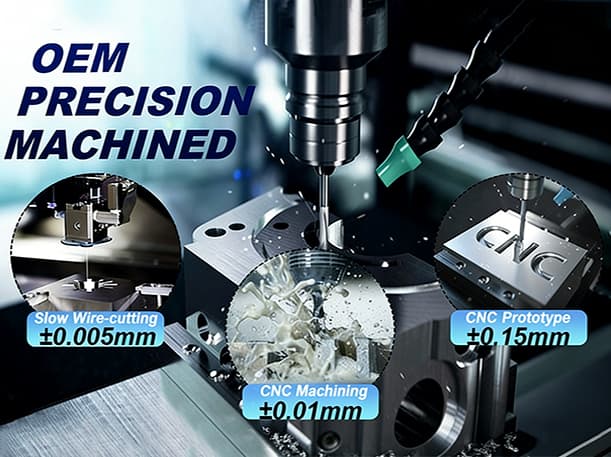

Precision Machining & Process Control

Precision is critical in silicone compression molding.

Our mold tooling is manufactured and refined using CNC machining to ensure accurate cavity dimensions, stable structures, and consistent performance throughout repeated production cycles.

Controlled machining and process parameters help maintain reliable pressure distribution and curing behavior during compression molding.

Manufacturing Standards & Certifications

Our manufacturing processes are operated under structured quality management systems and recognized manufacturing standards.

These standards support stable production control, material traceability, and consistent manufacturing practices across silicone compression molding projects.

PATENT CERTIFICATE

Tooling Experience & Engineering Know-How

Years of tooling development and engineering experience allow us to optimize mold structures, part geometry, and material flow for silicone compression molding.Our accumulated know-how supports efficient mold design, reliable production, and long-term tooling durability across different application requirements.