Silicone Material: Coloring, Mixing Techniques, and Industrial Applications

What Is Silicone Material?

Silicone material is a synthetic polymer made from silicon, oxygen, carbon, and hydrogen. It is widely known for flexibility, durability, and heat resistance. Unlike plastic, silicone does not easily degrade under extreme temperatures, making it a reliable option for multiple industries.

Silicone material is used in food-grade molds, medical devices, automotive parts, and electronic seals. For B2B buyers, it provides stable performance and compliance with international safety standards. Many factories provide OEM and ODM services to design custom silicone products for specific market demands.

Silicone Material Coloring: Key Techniques and Options

Common Coloring Methods

Silicone material can be colored using pigments or silicone colorants. Pigments are highly concentrated and produce deep, uniform colors. Colorants are easier to mix and are often used in smaller production runs, though the results may be less intense for large-scale projects.

How to Dye Silicone Correctly

The coloring process is done before curing. The pigment or colorant is added to the silicone base and blended until the mixture is even. Proper temperature control during curing prevents separation and ensures consistent results. This step is critical for achieving professional-quality silicone molds or parts.

![]()

Color Customization for Branding

B2B clients often request custom colors to strengthen branding. Pantone color matching is used to ensure accuracy. Popular choices include transparent tones for food molds, pastel colors for consumer goods, and neon finishes for promotional products.

Mixing Silicone: Industrial and DIY Approaches

Mixing Ratio

Silicone material typically uses two components: a base and a curing agent. The correct ratio is essential for product quality. Too much curing agent results in brittle silicone, while too little leaves the surface tacky.

Industrial Mixing

In large-scale production, silicone is mixed with high-speed vacuum machines. This removes air bubbles and ensures a smooth, consistent material. Industrial mixing guarantees safety and compliance, especially for FDA and LFGB certified products.

DIY Mixing

Small-scale mixing is possible for personal projects, but it is not recommended for commercial use. Hand mixing often creates uneven results and may not meet international safety standards.

Applications of Colored Silicone Material in B2B Markets

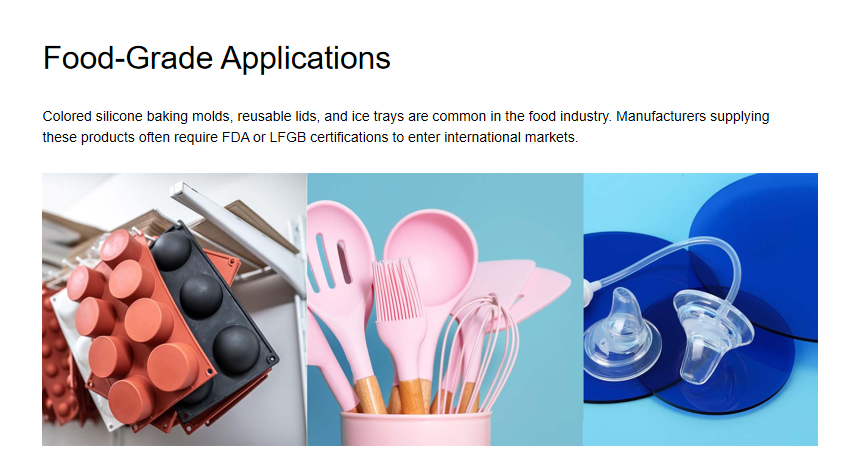

Food-Grade Applications

Colored silicone baking molds, reusable lids, and ice trays are common in the food industry. Manufacturers supplying these products often require FDA or LFGB certifications to enter international markets.

Medical-Grade Uses

Silicone is hypoallergenic and biocompatible, making it suitable for tubing, medical seals, and baby products such as pacifiers. Custom coloring helps brands distinguish their products in competitive healthcare markets.

Electronics and Automotive

Silicone gaskets, seals, and keypad components are widely used in electronics and cars. The material’s resistance to extreme heat and chemicals ensures long-term durability.

Promotional and Branding

Silicone wristbands, cup lids, and giveaways are often customized with colors and logos. These products combine low production costs with high marketing value.

B2B Considerations: Custom Orders, MOQ, and Certifications

For B2B buyers, ordering silicone products involves several important factors.

-

Customization options: factories can design molds, colors, and packaging

-

Minimum order quantity: often 500 to 1000 units, depending on design complexity

-

Certifications: FDA and LFGB for food-grade, RoHS and REACH for electronics

-

Bulk consistency: industrial mixing ensures stable color and quality in large volumes

These elements distinguish professional silicone manufacturing from small DIY projects.

FAQ: Common Questions About Silicone Material and Coloring

Q1: Can you dye silicone at home

Yes, but only for personal projects. Industrial mixing is required for professional quality and safety.

Q2: What is the difference between silicone pigment and silicone colorant

Pigments are concentrated and create stronger colors, while colorants are easier to use for small runs.

Q3: Which certification is better for food contact, FDA or LFGB

Both are safe. FDA is widely accepted in the United States, while LFGB is stricter and preferred in Europe.

Q4: What industries use colored silicone most often

Food, medical, automotive, electronics, and promotional products rely heavily on custom silicone.

Q5: What is the lead time for OEM silicone products

Sampling usually takes one to two weeks, while bulk production may require three to four weeks depending on the order size.

Conclusion

Silicone material is one of the most versatile industrial polymers today. Its ability to be colored, mixed, and molded makes it essential for a wide range of applications. For B2B buyers, silicone offers not only flexibility but also compliance with international certifications.

By working with a qualified OEM or ODM silicone manufacturer, businesses can order custom silicone molds, certified food-grade products, and bulk shipments that align with branding and market demands. Partnering with the right supplier ensures reliable quality and strong competitive advantage.