Introduction

At CoolniceMFG, our custom silicone printing services help brands and OEM manufacturers choose the right printing process for each product design. Printing plays a vital role in how your silicone products look, feel, and perform. Selecting the correct method ensures durability, color accuracy, and a premium appearance — while reducing costs and improving efficiency.

1. Why Choosing the Right Printing Method Matters

Different silicone products demand different printing approaches.

A misaligned or faded logo can weaken brand perception, while high-precision printing enhances value and usability. Proper selection affects:

-

Durability: Resistance to stretching, heat, and washing.

-

Color Quality: Vibrancy and long-term stability.

-

Cost Efficiency: Balancing setup cost with batch volume.

-

Lead Time: Faster setup equals quicker delivery.

2. Main Silicone Printing Methods

Silk Screen Printing

Ideal for flat or slightly curved surfaces.

-

Advantages: Thick ink deposit, vibrant colors, excellent UV and abrasion resistance.

-

Limitations: Each color needs a separate screen; slower for multi-color jobs.

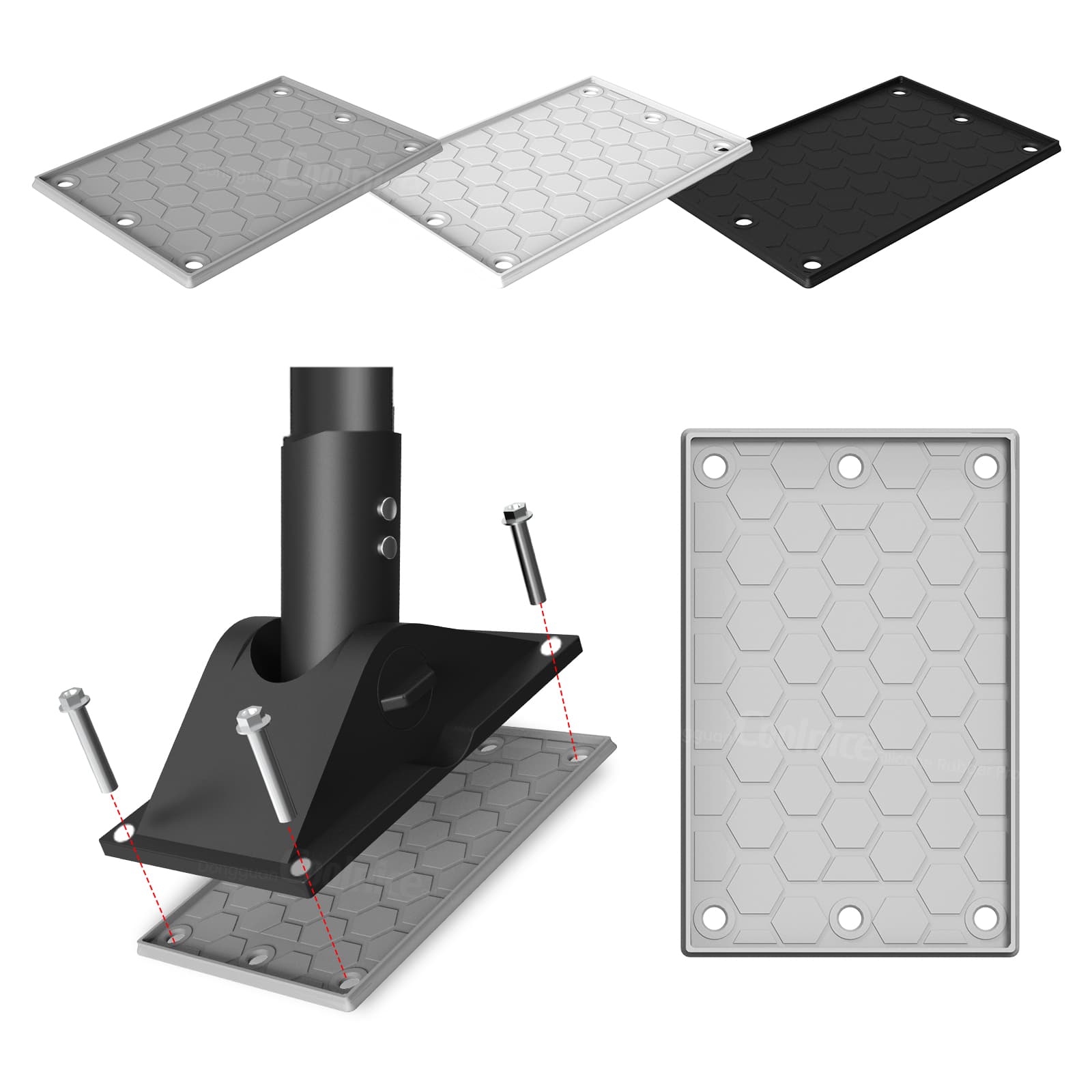

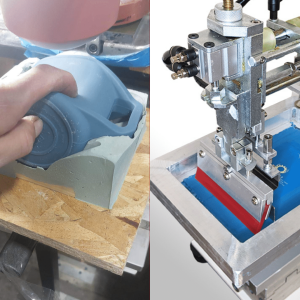

Pad Printing

Perfect for curved or irregular parts.

-

Advantages: Transfers detailed logos precisely; efficient for small parts.

-

Limitations: Thinner ink layer and smaller print area than screen printing.

Digital UV Printing

Best for photo-quality or gradient effects.

-

Advantages: No plate or screen required; fast setup.

-

Limitations: Slightly less elastic than silicone-based inks.

Heat Transfer Printing

Great for large graphics and multi-color designs.

-

Advantages: High-definition results; durable and consistent.

-

Limitations: Higher film and setup cost.

IMD / IMR (In-Mold Decoration)

Integrates printed film directly during molding.

-

Advantages: Exceptional durability, scratch and chemical resistance.

-

Limitations: Higher tooling investment; suited for mass production.

3. Key Factors to Consider

| Factor | What to Evaluate | Recommended Method |

|---|---|---|

| Surface Shape | Flat, curved, or 3D | Screen → flat; Pad/Transfer → curved |

| Color Complexity | Single vs Multi-color | Screen → simple; UV/Transfer → multi-color |

| Durability Needs | Indoor vs Outdoor use | IMD or Co-Injection for maximum life |

| Production Volume | Small vs Large | Pad/UV → small; Screen/IMD → large |

| Budget Range | Tooling and setup costs | Pad printing = lowest setup; IMD = highest |

4. Cost and Durability Comparison

| Method | Initial Cost | Durability | Color Saturation | Production Speed |

|---|---|---|---|---|

| Screen Printing | ★★☆☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Pad Printing | ★☆☆☆☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| UV Printing | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ | ★★★★☆ |

| Heat Transfer | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| IMD / IMR | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

5. How CoolniceMFG Helps You Decide

Our engineering team evaluates every project based on design, surface, and expected performance.

With FDA, LFGB, and REACH-certified inks, CoolniceMFG ensures each printed part meets the highest global standards.

We provide prototyping, material testing, and pilot production so you can confirm quality before mass manufacturing.

6. Real-World Applications

-

Pad Printing: Brand logos on medical buttons or watch straps.

-

Screen Printing: Colorful graphics on silicone mats and lids.

-

Heat Transfer: Promotional gifts with full-color imagery.

-

IMD: Embedded, scratch-resistant logos on automotive or electronic parts.

Each process delivers a different balance between appearance, cost, and durability — and our team ensures you pick the one that fits best.

7. Final Thoughts

Choosing the right silicone printing process helps you create long-lasting, high-quality products that truly represent your brand.

Partnering with CoolniceMFG means getting professional engineering support, flexible order volumes, and the latest printing technologies all in one place.