How Custom Silicone Mold Design Shapes Product Quality

Introduction

In silicone manufacturing, every great product begins with a precise mold.

A well-engineered custom silicone mold design determines not only the shape and look of a product, but also its durability, flexibility, and performance.

![]()

At CoolniceMFG, we believe mold design is not just a technical step—it is the foundation of product quality. Whether you are producing kitchenware, beauty tools, or industrial components, your silicone mold defines how the final product feels, functions, and lasts.

What Is Custom Silicone Mold Design?

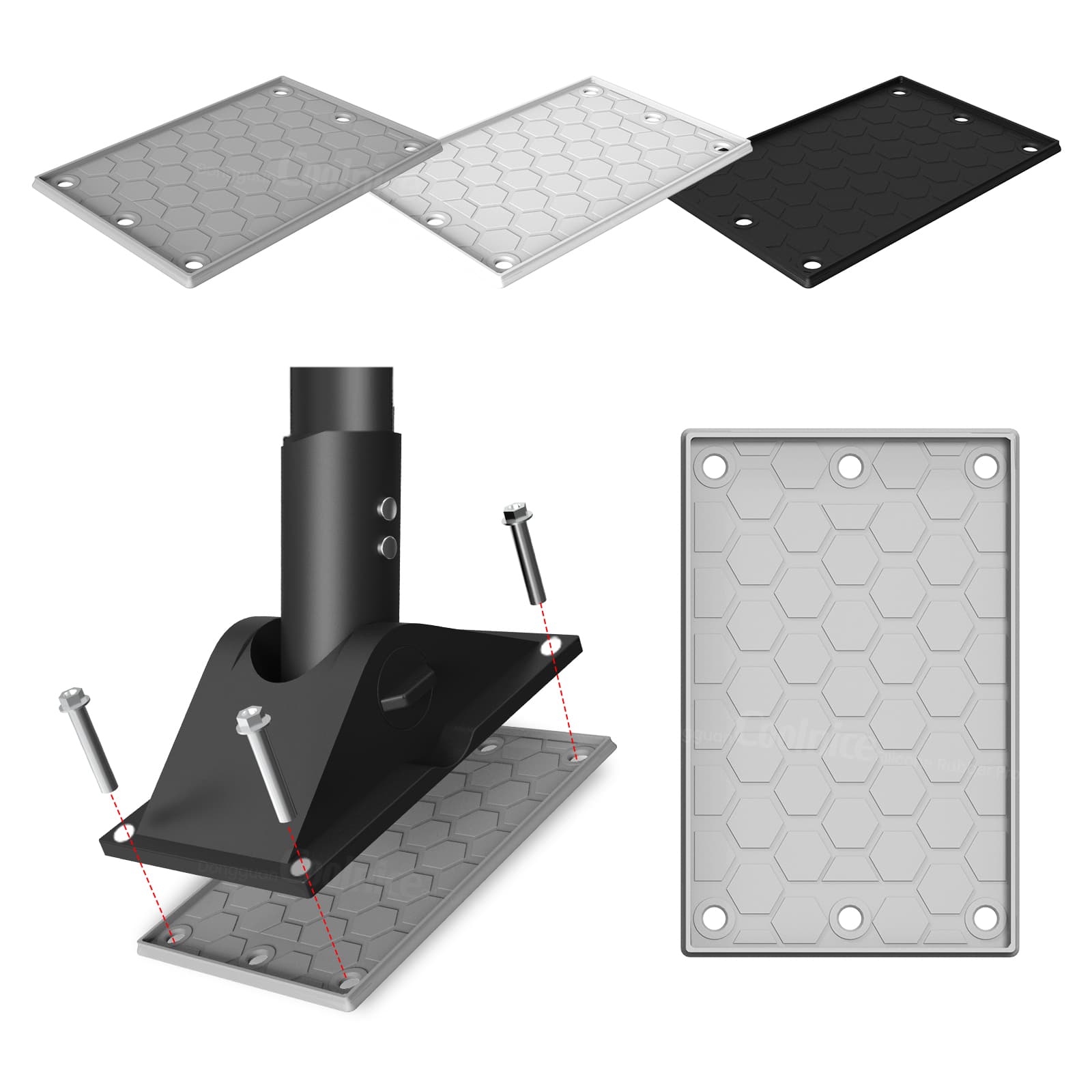

Custom silicone mold design refers to the process of creating a mold that perfectly fits the product’s intended form, size, and usage.

Unlike generic molds, custom molds are engineered using CAD (Computer-Aided Design) software and precision CNC machining to meet specific design and functional requirements.

A high-quality silicone mold must balance:

-

Dimensional accuracy

-

Material flow during molding

-

Surface smoothness

-

Easy demolding

-

Long mold life under repeated production cycles

Each of these factors influences how silicone behaves during molding—and how the final product performs in real-world use.

Why Mold Design Matters for Product Quality

1. Precision Equals Consistency

A precisely machined mold ensures that every molded part has consistent dimensions and surface detail.

In large-scale silicone molding production, even a 0.1mm deviation can cause visible defects or poor fit.

2. Improved Material Flow and Strength

Proper gate and vent design allows silicone to flow evenly, eliminating air bubbles and weak points.

This results in stronger and longer-lasting molded products.

3. Surface Quality and Brand Perception

A finely polished mold surface leads to smoother finishes and enhances product appeal.

Whether it is a glossy beauty tool or a matte kitchen accessory, the mold finish defines how customers perceive quality.

4. Reduced Defects and Production Waste

Optimized silicone mold design minimizes material waste and reduces defective parts, improving manufacturing efficiency for OEM and FBA clients.

The Design-to-Production Workflow

At CoolniceMFG, we follow a systematic workflow to ensure that each custom silicone mold meets the highest international standards.

Step 1: Concept and 3D CAD Modeling

Our design team transforms your product idea into a 3D model, taking into account shrinkage rate, wall thickness, and draft angles for smooth demolding.

Step 2: Structural Analysis and Prototyping

We create prototypes using 3D printing or soft tooling to verify design accuracy, ergonomics, and material compatibility.

Step 3: CNC Machining and Mold Fabrication

Precision CNC machining ensures accurate cavity dimensions, stable mold temperature, and tight tolerances for long mold life.

Step 4: Silicone Molding Process

Depending on the application, we apply compression molding, injection molding, or transfer molding to achieve the best results.

Step 5: Quality Control and Mold Verification

Each mold is inspected for dimensional accuracy, balance, and surface quality before mass production begins.

Common Design Mistakes to Avoid

-

Poor Venting Paths – trapped air can lead to incomplete fills or visible voids.

-

Shallow Draft Angles – makes demolding difficult and increases part damage.

-

Over-Polished Cavities – causes silicone slippage and uneven texture.

-

Inconsistent Wall Thickness – results in weak spots and deformation.

-

Improper Gate Design – leads to uneven silicone flow and defects.

CoolniceMFG’s engineering team uses simulation software to predict material flow and eliminate these issues before mold cutting begins.

Applications of Custom Silicone Mold Design

| Industry | Common Products | Design Focus |

|---|---|---|

| Kitchenware | Baking molds, spatulas, ice trays | Food-grade silicone, easy release |

| Beauty & Wellness | Ice rollers, massage cups | Smooth surface, ergonomic shape |

| Consumer Goods | Wristbands, phone cases | Flexibility, repeatability |

| Industrial | Seals, gaskets, insulation parts | Dimensional stability |

| Promotional & Gift | Logo molds, decorative shapes | Dual-color or marble patterns |

A precise mold design ensures reliability, repeatability, and strong market performance across all these industries.

How CoolniceMFG Ensures Quality

20+ Years of Manufacturing Experience

We have delivered more than 10,000 custom silicone mold projects for OEM and ODM clients worldwide.

Complete In-House Production

From custom silicone mold design to tooling, molding, and packaging, every step is completed in our factory for full quality control.

Advanced Tooling Equipment

CNC centers, EDM tools, and 3D scanners guarantee micron-level precision and consistency.

Certified Materials and Compliance

All materials are FDA, LFGB, ROHS, and REACH compliant—safe for food-grade, cosmetic, and industrial uses.

End-to-End OEM Support

We also provide packaging design, labeling, and logistics for private-label and FBA clients.

Partner With CoolniceMFG

If you are planning to develop a new silicone product, choosing the right mold partner is essential.

Our experienced engineers and technicians can turn your concept into a durable, high-quality product with precise custom silicone mold design.

Learn more about our full Custom Silicone Mold manufacturing solutions and start your next project with CoolniceMFG today.