The Complete Guide to Silicone Printing Techniques and Their Applications

Introduction

In the world of silicone product manufacturing, choosing the right surface decoration method is key to creating high-quality, customized designs. At CoolniceMFG, our custom silicone printing services combine advanced technology and certified materials to deliver precise, durable, and visually appealing results.

From wearable bands to kitchen tools and medical components, printing and surface decoration transform simple silicone products into branded, professional-looking items.

This article explains the most widely used silicone printing techniques, their strengths, and how to choose the right one for your project. Whether you are a brand owner, OEM manufacturer, or designer, this guide will help you understand every major process — and how CoolniceMFG’s custom silicone printing services can deliver durable and precise results.

1. What Is Silicone Printing?

Silicone printing refers to applying logos, graphics, or patterns onto silicone surfaces using specialized inks.

Because silicone has low surface energy, traditional inks cannot adhere properly. Therefore, printing on silicone requires silicone-based inks formulated to bond chemically to the substrate after curing.

The result is a printed surface that remains flexible, waterproof, and colorfast — even when stretched, washed, or exposed to heat. Silicone printing is used in numerous industries, including medical devices, promotional gifts, consumer goods, and industrial applications.

2. Why Silicone Printing Matters

High-quality printing is not just about aesthetics — it directly enhances product value and usability.

-

Brand Visibility: Add corporate logos, color themes, and product details.

-

Functionality: Print measurement scales, indicators, or safety marks.

-

Durability: Printed designs resist wear, moisture, and UV light.

-

Customization: Perfect for OEM/ODM brands that need flexible, short-run production.

At CoolniceMFG, our printing processes ensure clear, long-lasting designs that reflect your brand identity.

3. Overview of Major Silicone Printing Techniques

There is no single method that fits all products. Each printing process is suitable for different surface types, production volumes, and design complexities. Below are the most common techniques used for silicone decoration today.

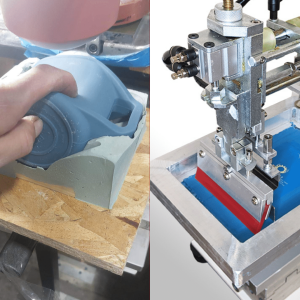

3.1 Silk Screen Printing

Silk screen printing pushes ink through a mesh stencil onto a flat or slightly curved surface.

-

Advantages: Creates thick, vibrant layers of color; strong UV and abrasion resistance.

-

Best For: Flat silicone items such as mats, covers, or panels.

-

Limitations: Each color requires its own screen and alignment, which can slow production.

3.2 Pad Printing

Pad printing transfers ink from an etched steel plate onto a product using a soft silicone pad.

-

Advantages: Excellent for curved or irregular shapes; allows detailed logos on small parts.

-

Best For: Bottle caps, watch bands, medical buttons, and keychains.

-

Limitations: Ink layer is thinner, and color saturation is slightly lower than screen printing.

3.3 Digital UV Printing

Digital UV printing applies full-color CMYK designs directly onto silicone surfaces using UV-curable inks.

-

Advantages: Supports gradient and photo-quality effects; no need for plates or screens.

-

Best For: Custom promotional products or limited-edition runs.

-

Limitations: Slightly less elastic than silicone-based inks.

3.4 Heat Transfer Printing

Heat transfer uses pre-printed films and applies them to silicone with heat and pressure.

-

Advantages: High-resolution, full-color graphics; consistent results in mass production.

-

Best For: Promotional items, consumer goods, and branded accessories.

-

Limitations: Higher setup cost for transfer films.

3.5 Water Transfer Printing

Also known as hydrographics, this technique immerses the product into water where a printed film floats on the surface.

-

Advantages: Wraps around complex 3D shapes seamlessly.

-

Best For: Automotive components, helmets, and decorative parts.

-

Limitations: Slower process, best for high-value applications.

3.6 Dispensing (Color Dropping)

Liquid silicone pigment is precisely dispensed into mold cavities before baking or curing.

-

Advantages: Produces embossed or multi-layered effects with excellent color strength.

-

Best For: Embossed logos, labels, or custom patterns.

-

Limitations: Higher mold cost and moderate efficiency.

3.7 IMD / IMR (In-Mold Decoration / In-Mold Rolling)

A printed film is inserted into the mold and permanently fused into the product during molding.

-

Advantages: Superior durability — scratch, chemical, and wear-resistant.

-

Best For: High-end electronics, automotive interiors, and cosmetic packaging.

-

Limitations: Requires high-precision film positioning; not ideal for small runs.

3.8 Co-Injection Molding

Two silicone or plastic materials are injected together, embedding color or pattern directly into the part.

-

Advantages: Creates seamless dual-color products with no post-printing needed.

-

Best For: Handles, grips, or products needing color contrast.

-

Limitations: High tooling investment; suited for mass production.

4. Quick Comparison Table

| Printing Method | Surface Type | Color Quality | Durability | Production Scale |

|---|---|---|---|---|

| Silk Screen Printing | Flat / Slight Curve | ★★★★★ | ★★★★☆ | Medium–High |

| Pad Printing | Curved / Small | ★★★★☆ | ★★★☆☆ | Medium |

| Digital UV Printing | Flat / Gradient | ★★★★☆ | ★★★☆☆ | Low–Medium |

| Heat Transfer | Flat / Large Area | ★★★★★ | ★★★★☆ | High |

| Water Transfer | Complex 3D | ★★★★☆ | ★★★☆☆ | Medium |

| Dispensing | 3D Logo Effect | ★★★★★ | ★★★★★ | Low–Medium |

| IMD / IMR | Flat / Embedded | ★★★★☆ | ★★★★★ | High |

| Co-Injection | Dual-color Mold | ★★★★☆ | ★★★★★ | High |

5. How to Choose the Right Silicone Printing Method

The correct printing process depends on shape, color complexity, and durability requirements.

| Factor | Recommendation |

|---|---|

| Surface Shape | Flat → Screen Printing; Curved → Pad or Transfer Printing |

| Color Complexity | Simple Logo → Screen; Multi-Color → UV or Heat Transfer |

| Durability Needs | Outdoor / Industrial Use → IMD or Co-Injection |

If you’re unsure which technique fits your project, CoolniceMFG’s engineers can help evaluate your design and recommend the optimal process.

6. Why Choose CoolniceMFG

At CoolniceMFG, we combine precision silicone molding with advanced printing capabilities — all under one roof.

Our Advantages:

-

20+ years of OEM/ODM experience

-

In-house equipment for screen, pad, UV, and IMD printing

-

FDA, LFGB, and REACH certified inks

-

Professional Pantone color matching

-

Flexible MOQ from sampling to full production

Whether you need large-volume screen printing or small-batch digital printing, CoolniceMFG ensures consistent quality and reliable delivery for every order.

7. Final Thoughts

Silicone printing blends creativity with technical expertise. By choosing the right process, you can achieve bold colors, durable finishes, and professional branding for your silicone products.

At CoolniceMFG, our custom silicone printing services help you bring every idea to life — with precision, safety, and long-lasting visual impact.