Silicone Wristband Manufacturer Guide: Process, Printing, Sizes, MOQ & Lead Time

If you are sourcing from a silicone wristband manufacturer, this guide gives you the facts you need to move from idea to shipment with confidence. We cover materials and compliance, molding options, silicone wristband printing, size choices, and the silicone wristbands MOQ you should plan for. Use this as a checklist when you brief Coolnice or any silicone wristband manufacturer.

Why brands choose silicone wristbands (vs. “rubber bands”)

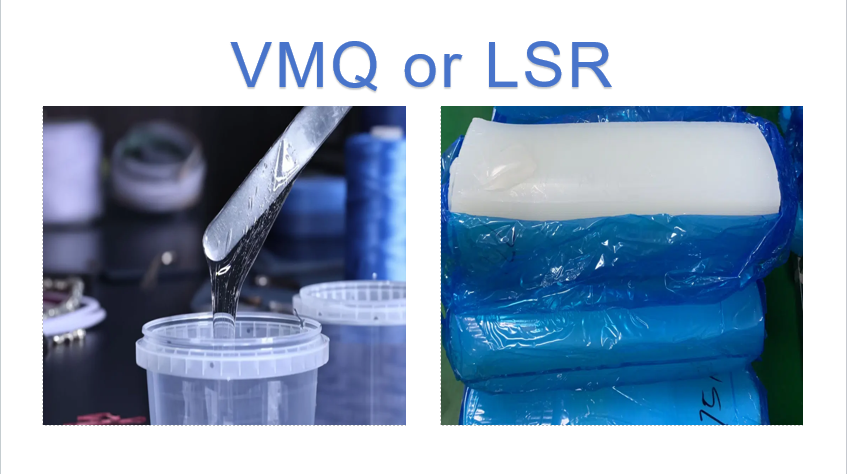

Silicone wristbands are not classroom rubber-band crafts. They are molded from stable VMQ or LSR silicone wristbands compounds for long wear and clean branding.

-

Skin contact friendly: can meet ISO 10993 and pass RoHS/REACH.

-

Heat/UV resistant: shape holds up outdoors and after wash cycles.

-

Color control: Pantone-matched custom silicone wristbands stay on brand.

-

Repeatable QC: molded parts deliver stable dimensions and prints.

-

Decoration-ready: debossed, color-fill, emboss, silk screen, and UV digital.

When fundraising, retailing, or launching teams, a proven silicone wristband manufacturer gives durability and regulatory comfort with repeatable quality.

Materials & compliance (what to ask for)

A qualified supplier should specify:

-

Base polymer: VMQ (solid silicone for compression) or LSR (liquid silicone for injection).

-

Durometer: Shore A 40–60 for most use cases.

-

Pigments: heavy-metal free; Pantone codes accepted.

-

Compliance: RoHS/REACH; ISO 10993 for skin-contact projects.

-

Note: bands are not food-contact parts by default; don’t claim “food grade” unless required.

Ask your silicone wristband manufacturer for a one-page TDS, test plan, and a sample path.

Production processes (choose for cost, detail, and volume)

Compression molding (solid silicone, HTV)

Mixed silicone + color masterbatch → cut slugs → heated mold → cure → trim.

Why choose: cost-effective tooling, fast color changes, ideal for debossed silicone wristbands, embossed logos, and color-fill.

LSR injection molding (liquid silicone)

Two-part LSR metered/mixed → cold runner injection → heat cure in closed mold.

Why choose: tight tolerances, clean parting lines, high output for premium LSR silicone wristbands. Tooling cost is higher but repeatability is excellent.

Multicolor & effects

Swirl/segment colors, glow, glitter. Overmolding is possible for special SKUs.

Printing & decoration (look, budget, and wear)

A capable plant should offer multiple silicone wristband printing and molding finishes:

-

Debossed (engraved) – recessed logo; durable; best with color-fill.

-

Embossed (raised) – bold tactile effect for short logos.

-

Color-filled deboss – top pick for contrast and longevity.

-

Silk screen / pad print – sharp details at low cost; abrasion affects life.

-

UV digital print – full-color gradients and photos with protective topcoat.

Request a rub test on your chosen finish from the silicone wristband manufacturer if the bands will face sweat and sun.

Sizes, fit & thickness

Standard widths × thickness

-

12 × 2 mm (slim)

-

12 × 3 mm (slim thick)

-

20 × 2 mm (wide)

-

25 × 2 mm (extra wide)

Inner circumference

-

Adult: 202–210 mm (≈ 8.0–8.3″)

-

Youth: 180–190 mm (≈ 7.1–7.5″)

-

Child: 160–170 mm (≈ 6.3–6.7″)

When you brief sizes, name the section “silicone wristband sizes” in your PO to avoid confusion. Ask for a fit sample pack and a Pantone color deck to lock decisions fast.

Color control & packaging

-

Pantone matching: submit brand codes; approve a photo swatch or physical sample.

-

Finish: matte (most common) or satin.

-

Packaging: bulk polybag, individual OPP, header card, or retail box.

-

For wholesale: specify “silicone bracelets bulk” packing with carton CBM and weight for easy freight booking.

MOQ, tooling & lead time (what drives cost)

Typical silicone wristbands MOQ

-

Compression: 100–300 pcs per color/design.

-

LSR injection: more economical at 500–1,000+ pcs.

Tooling

-

Compression mold: low–moderate cost; 1–2 weeks build.

-

LSR mold: higher cost; 2–3 weeks; best parting lines.

Lead time (after approval)

-

Deboss/color-fill: 10–18 days for standard volumes.

-

UV/screen print: add 2–4 days.

-

Multicolor effects or peak season: plan 3–4 weeks.

Cost drivers: band width/thickness, decoration type & color count, SKU split, packaging spec, and compliance testing. A transparent silicone wristband manufacturer will quote each driver with options to hit your target.

Quality control (how good factories avoid surprises)

-

Incoming: verify compound and pigments vs. TDS; record ΔE.

-

In-process: log cure temp/time; sample each cavity for width, thickness, seam.

-

Decoration: adhesion test, color-fill completeness, print registration.

-

Final: AQL on dimensions, defects, logo clarity, count/pack.

-

Docs: COA, RoHS/REACH; ISO 10993 on request.

Ask to see real QC records during vendor selection.

Case snapshots

-

Fundraiser – 3 colors, deboss + fill, 5,000 pcs: compression, Pantone match, bulk pack → ~14–18 days after sample OK.

-

Retail launch – UV full-color, 2 widths: compression + UV, retail carded pack, barcode labels → 18–25 days.

-

Sports team – embossed wide band, 10,000 pcs: LSR for crisp edges; home/away color mix → 20–25 days incl. mold.

How to brief your manufacturer (copy this)

-

Brand Pantone + vector art (AI/PDF)

-

Band spec: inner circumference(s), width × thickness, durometer

-

Finish: deboss/emboss/color-fill/print (with color callouts)

-

Compliance: RoHS/REACH; ISO 10993 if needed

-

Packaging: bulk or retail; barcode plan

-

Qty split by SKU (size × color)

-

Delivery terms & target date (FOB/CIF/DDP)

This helps any silicone wristband manufacturer quote fast and cut revisions.

FAQs

Q: What finish lasts longest outdoors?

Deboss + color-fill balances clarity and wear. Prints last longer with a topcoat.

Q: Can one mold cover several widths?

No. Width change needs new tooling. Minor circumference changes may share inserts.

Q: Do you handle wholesale?

Yes. We support silicone bracelets bulk programs with carton labeling, barcodes, and retail packs.

Q: Small test order first?

We accept low starts aligned with the silicone wristbands MOQ above, then scale.

Call to action

Coolnice is a production-ready silicone wristband manufacturer. We build custom silicone wristbands via compression and LSR, offer deboss/emboss/color-fill, silk screen, and UV digital, lock silicone wristband sizes with fit samples, and meet your silicone wristbands MOQ with stable lead times. Send your artwork and date, and get a priced plan plus sample path today.