How Custom Silicone Ice Cube Rollers Are Made: A Cooling Innovation for Everyday Use

The silicone ice cube roller has become one of the most versatile and in-demand cooling tools in both the beauty and wellness industries.

From skincare and face massage to household and medical cold therapy, it offers a convenient and reusable solution for cooling needs.

![]()

At CoolniceMFG, a professional silicone ice roller manufacturer, we design and produce custom silicone ice cube rollers that combine comfort, functionality, and safety for global OEM and private-label clients.

Step 1 – Product Design and Material Selection

Every great custom silicone ice cube roller starts with thoughtful design.

CoolniceMFG’s engineering team works closely with brand owners to design ergonomic roller shapes that fit the face and body contours perfectly.

We use 100% food-grade and skin-safe silicone materials that are BPA-free, LFGB-, and FDA-certified, ensuring safety for cosmetic and personal care applications.

Our silicone shells are soft, flexible, and temperature-resistant, providing a smooth and consistent cooling effect.

Depending on customer preference, the ice roller can be designed with refillable ice compartments or integrated cooling gel to meet different functional needs.

![]()

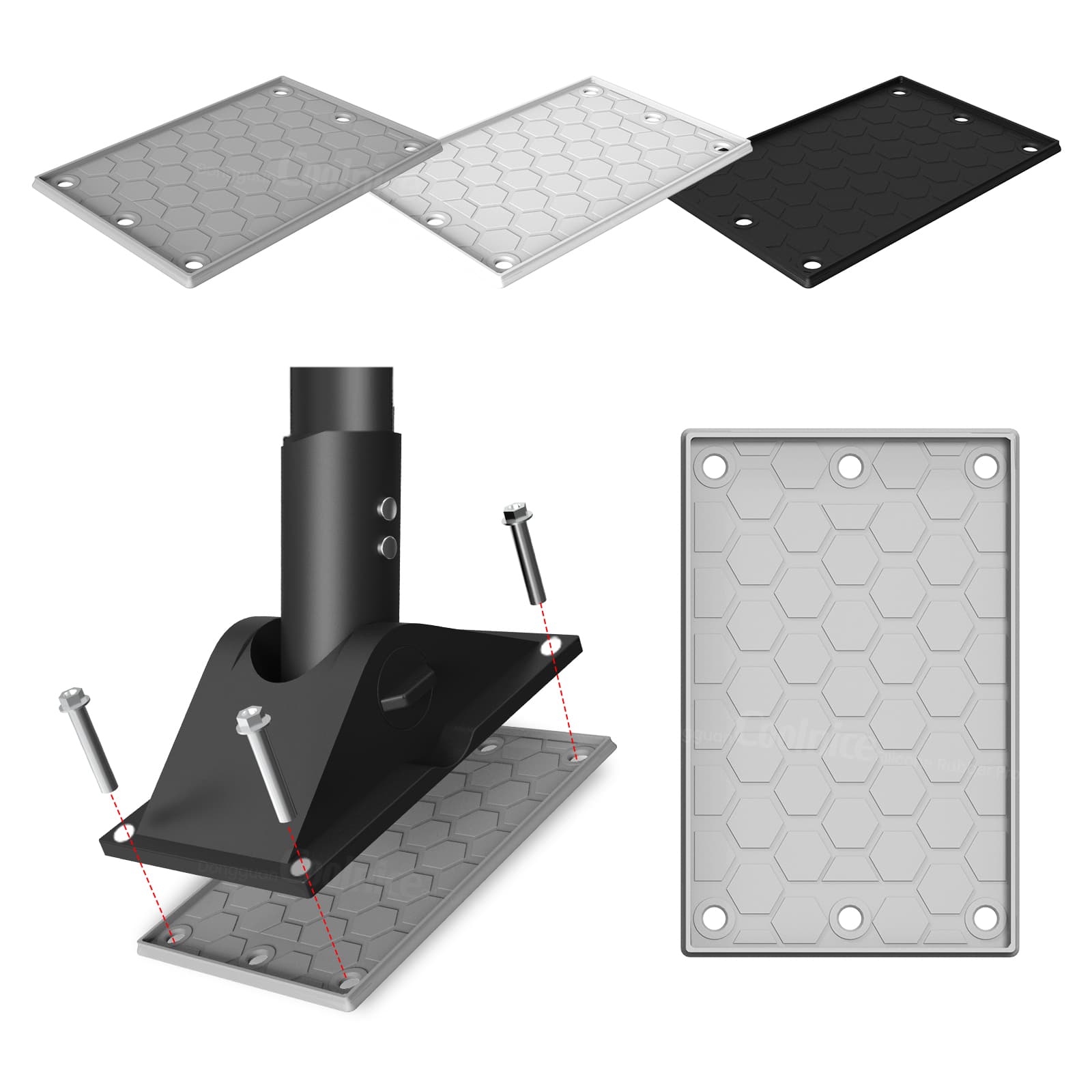

Step 2 – Mold Creation and Silicone Molding

Once the design is approved, the mold is created using precision CNC machining.

CoolniceMFG specializes in custom silicone mold manufacturing, enabling accurate dimensions and detailed surface finishes.

Through compression molding or injection molding, we ensure every silicone roller is formed with a seamless structure, leak-proof joints, and comfortable handling texture.

After molding, each part is cured, trimmed, and inspected before assembly.

![]()

Our production team can manufacture ice rollers in various shapes — cylindrical, rounded, or sculpted heads — ideal for facial massage or body cooling therapy.

Step 3 – Cooling Gel and Assembly

For rollers with built-in gel cores, we use non-toxic cooling gel formulas that maintain temperature stability for longer use.

Each silicone roller undergoes a controlled gel injection process, ensuring uniform distribution inside the roller.

The roller body and handle are assembled with medical-grade fittings and sealed to prevent leakage.

Before packaging, all units are tested for freezing endurance and performance stability.

Step 4 – Branding and Packaging Customization

CoolniceMFG supports full OEM and ODM customization for all custom silicone ice cube rollers, including:

-

Pantone color matching

-

Brand logo engraving or printing

-

Multi-color molding

-

Eco-friendly retail and gift packaging

These customization options allow our clients to launch unique skincare or wellness products under their own brands, fully supported by CoolniceMFG’s factory-level quality control.

Step 5 – Quality Testing and Global Shipping

All silicone ice rollers pass through strict testing for:

-

Cold endurance and temperature retention

-

Durability and flexibility

-

Material safety and sealing integrity

Our facility is certified under ISO9001, SA8000, BSCI, and complies with FDA, LFGB, and ROHS standards.

Products can be shipped in FBA-ready packaging, suitable for Amazon or global distribution.

Applications of Silicone Ice Cube Rollers

| Category | Usage |

|---|---|

| Skincare & Beauty | Tightening pores, reducing puffiness, and soothing skin. |

| Medical & Recovery | Relieving swelling, pain, or minor injuries. |

| Wellness & Massage | Cooling therapy for muscles and post-exercise recovery. |

| Promotional & Gift | Custom-designed rollers for branding and cosmetic retailers. |

These ice rollers combine elegance and function, becoming a key product for beauty and cold therapy lines.

Why Choose CoolniceMFG as Your Silicone Ice Roller Manufacturer

-

20+ years of silicone molding and OEM production experience

-

In-house design, tooling, and molding capabilities

-

Support for small-batch private-label production

-

FDA-, LFGB-, ROHS-, and REACH-certified materials

-

FBA-ready packaging and fast international shipping

Manual Assembly and Inspection Process

Skilled Mold Technicians at Work

Organized Mold Component Storage

Automated Sorting for Silicone Products

CoolniceMFG helps global brands bring innovative custom silicone ice cube rollers to life with reliable production and consistent quality.

Get Started with Your Custom Silicone Ice Cube Roller Project

Looking to develop your own silicone ice roller line?

CoolniceMFG offers complete OEM/ODM manufacturing solutions, from concept and mold design to packaging and shipping.

Contact our team today to discuss your project requirements or request free samples.

Visit our Custom Silicone Products page to learn more.

FAQ

Q1: What materials are used in silicone ice cube rollers?

A1: We use food-grade, BPA-free silicone and non-toxic cooling gel, certified by FDA and LFGB for safe skincare and personal use.

Q2: Can I customize the roller shape and color?

A2: Yes, CoolniceMFG supports custom shapes, Pantone colors, and brand logo printing for OEM/ODM projects.

Q3: What’s the freezing time for a silicone ice roller?

A3: Typically 3–4 hours in a freezer provides up to 45 minutes of effective cooling therapy.

Q4: Do you provide private-label packaging?

A4: Yes, we offer fully branded packaging designs suitable for retail and e-commerce markets.