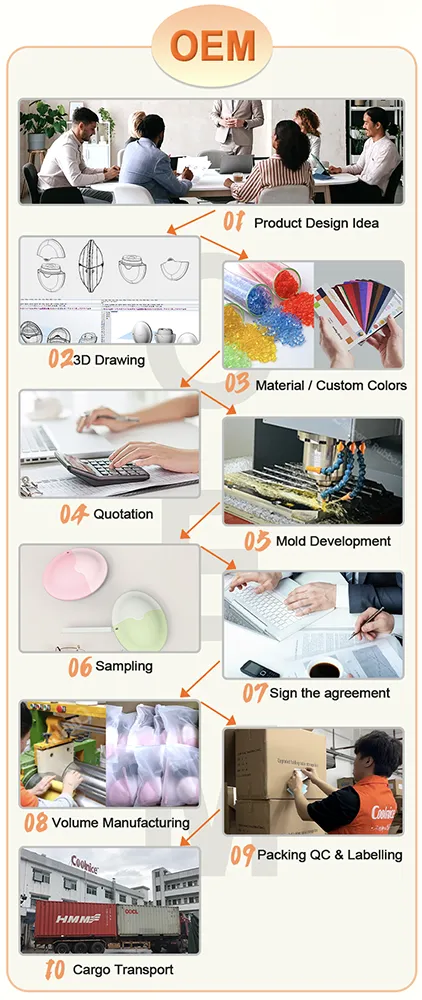

Mold Making Silicone: A Practical Guide for OEM and Business Use

In modern manufacturing, mold making silicone is one of the most reliable materials for producing detailed and reusable molds. Unlike one-time-use plastics, silicone molds can capture fine features and withstand repeated casting, making them suitable for industrial prototyping and small-scale production.

For businesses, understanding how to make a silicone mold goes beyond simple DIY. It is about efficiency, product testing, and quality assurance. This article explains how silicone mold making works in B2B, the tools required, and why companies choose OEM/ODM partners for bulk orders.

Why Businesses Choose Silicone for Mold Making

Silicone is widely used in industrial mold making because of its advantages:

-

Precision – captures fine lines and complex surfaces.

-

Durability – molds can be reused dozens of times without damage.

-

Heat Resistance – suitable for resins, plastics, wax, or even food products.

-

Cost Savings – useful for prototyping before investing in metal molds.

This flexibility makes silicone mould making essential for companies that need fast product validation or limited production runs.

Materials and Equipment for B2B Mold Making

Factory-scale mold production requires more advanced tools than hobby projects. Essential equipment includes:

-

Industrial-Grade Silicone Rubber – available in liquid or putty forms.

-

Mixing Machines – ensure accurate ratios for consistent results.

-

Mold Frames or Boxes – secure the master model for molding.

-

Vacuum Chambers – remove bubbles and improve mold density.

-

Release Agents – protect the master model and extend mold life.

In mold making with silicone, these tools guarantee stable performance for wholesale or OEM orders.

Step-by-Step: How to Make a Silicone Mold in Business Settings

Step 1: Preparing the Master Model

Select the product prototype or component. Clean it thoroughly before placing it in a mold frame.

Step 2: Mixing the Silicone

In industrial use, ratios must be precise. Automatic mixers ensure consistency in making a silicone mold for thousands of cycles.

Step 3: Pouring or Injection

The mixed silicone is poured or injected into the mold box. Controlled pouring ensures all details are captured.

Step 4: Curing Process

Curing is performed in temperature-controlled rooms. Businesses can speed up curing to meet deadlines.

Step 5: Demolding and Testing

Remove the cured mold carefully. Quality checks confirm flexibility, accuracy, and strength before it is used in bulk casting.

Industrial Applications of Silicone Mold Making

Silicone molds are used in many industries:

-

Consumer Goods – packaging, cosmetics, and home accessories.

-

Automotive and Electronics – prototyping rubberized parts and components.

-

Food and Beverage – food-grade molds for chocolate, ice, or promotional items.

-

Promotional Products – branded designs created with make your own silicone molds processes.

For B2B buyers, investing in making molds from silicone shortens lead time and reduces production risk.

Customization and OEM/ODM Services

Suppliers offer tailored solutions for business buyers:

-

Custom Dimensions – molds can be made for small or large components.

-

Branding Options – adding company logos with make your own mold solutions.

-

Material Grades – medical, food-safe, or industrial-grade silicone.

-

Bulk Orders – stable quality in diy silicone molding processes scaled for wholesale.

This flexibility is why many companies rely on OEM/ODM partners for silicone mould making.

Benefits of Partnering with Manufacturers

Working with a factory for silicone mold making offers advantages over retail kits:

-

Lower unit cost on bulk orders

-

Consistent quality from industrial-grade equipment

-

Faster delivery times with OEM production

-

Compliance with food or medical certifications

-

Reliable logistics for global buyers

This makes it practical for businesses to make silicone molds through professional suppliers.

FAQ: Business Queries About Silicone Mold Making

Q: What is the lead time for silicone mold orders?

A: Most factories deliver within 7–15 days, depending on order size.

Q: How many times can a mold be reused?

A: With proper handling, making a silicone mold allows dozens of uses.

Q: What industries benefit most?

A: Automotive, consumer goods, packaging, food-grade products, and promotional sectors.

Q: Can small MOQs be ordered?

A: Yes, many suppliers accept low-volume orders for testing before bulk runs.

Conclusion: Why Businesses Invest in Mold Making Silicone

For businesses, how to make a silicone mold is more than a workshop skill. It is an industrial tool for testing ideas, reducing costs, and producing consistent results.

From consumer goods to automotive components, mold making silicone supports innovation and flexibility. With OEM/ODM services, bulk orders, and professional equipment, making silicone molds is one of the most practical solutions for modern manufacturing.